Non-Newtonian fluid–structure interactions: Static response of a microchannel due to internal flow of a power-law fluid. Hydrodynamic Bulge Testing: Materials Characterization Without Measuring Deformation: If we want to use re-meshing, then we should use tet mesh, but then the question comes about using prism layers to capture BL effects. We should continue to use hex mesh, but switch off remeshingĢ.

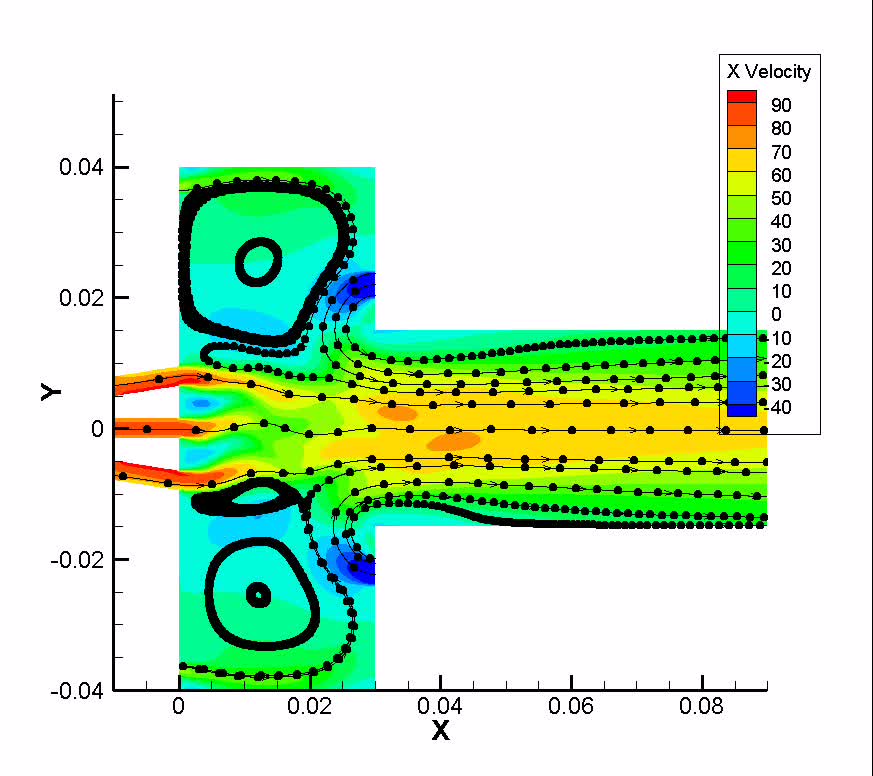

You can see the below papers by our group, where I have carried out the same simulation, but in steady state.ġ. To put in other words, you need a large amount of pressure to push the fluid through a long, narrow channel. The deflection is there becauseĪ: The top wall is made of soft material, PDMS, (which has elastic modulus of order of 1 MPa, compared to GPa for steel).ī: Due to lubrication approximation, nature of geometry, the hydrodynamic pressure is very high. Please advise on the basis of your rich knowledge and experience, how I should proceed. Īpart from these, I also ramped the data transfer pertaining to force and displacement in the System Coupling module and kept the time step to 10^-5.Įven then I have failed to get the simulation going past a few iterations, not even the first time step is converging. The adjacent cell height was taken to be the average height of the mesh (cell) in the fluid domain in the direction perpendicular to top wall. Declared the entire fluid domain, which is just beneath the top wall as Deforming.Ĥ. Declared the lower surface of the upper wall, which see the fluid domain, as System Coupling. I suspect that this is not particularly useful because Remeshing does not get invoked for hex mesh anyhow and my fluid domain is hex mesh.ģ. Used remeshing with minimum length scale and maximum length scale of 0.001 times minimum cell info and 100 times the maximum cell info. Used both diffusion based smoothing, with diffusion constant ranging from 1 to 3, and spring based smoothing, with spring constant value of 0.5.Ģ. While I have been able to succesfully carry out the simulation for steady state, the transient simulations are not converging due to "negative volume" problem in Fluent. The CFD is being carried out in Fluent with dynamic mesh option on, while the FEM is carried out in Transient Structural. We are using ANSYS Workbench for this 2 way coupled transient FSI simulation. Please see the attached image for geometry. The three walls of the rectangular microchannel, which includes the two side walls and the bottom walls, are rigid (no deformation) and the top wall is soft (deformable). Right now, I am trying to simulate transient FSI in a rectangular microchannel. My thesis is based on "Fluid Structure Interaction at Microscale".

I am a PhD Student in Mechanical Engineering. Dynamic mesh & Negative volume in 3D - CFD Online Discussion Forums

0 kommentar(er)

0 kommentar(er)